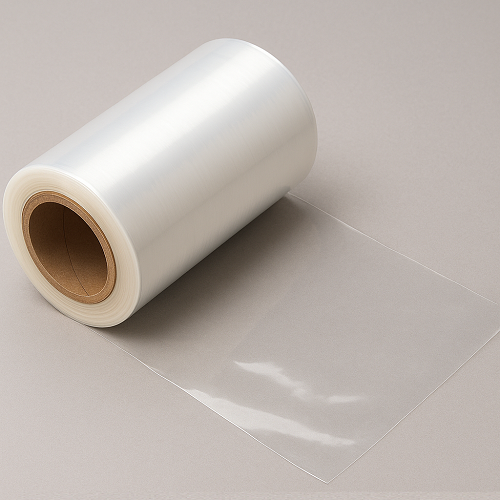

In today’s fast-paced world, food safety and convenience have become critical concerns for both consumers and manufacturers. Among the many packaging innovations, lidding film has emerged as one of the most versatile and reliable solutions. Often seen as the sealed cover on fresh food containers, ready meals, salads, yogurts, and meat trays, lidding films are more than just a plastic sheet—they are a sophisticated packaging material that ensures product quality, enhances shelf appeal, and supports sustainability.

What is Lidding Film?

Lidding film is a flexible plastic or composite film designed to seal containers such as trays, cups, and bowls. Its main function is to create an airtight barrier, keeping food fresh while preventing contamination, leakage, or tampering. Unlike standard wraps or lids, lidding films are engineered with advanced sealing technologies, making them easy to peel, puncture-resistant, and adaptable to different types of packaging.

Types of Lidding Films

Lidding films come in a wide range of structures and specifications to meet different packaging needs.

Some common types include:

- Peelable Films: Designed for consumer convenience, allowing easy removal without tearing or spilling.

- Resealable Films: Enable multiple openings and reclosures, ideal for products like deli meats or snacks.

- High-Barrier Films: Provide superior protection against oxygen, moisture, and UV light, extending shelf life.

- Anti-Fog Films: Maintain visibility of products even in cold storage by preventing condensation.

- Die-Cut Lids: Pre-shaped circular or custom-cut seals, often used for yogurt cups, coffee capsules, or single-serve products.

Materials Used in Lidding Film

Modern lidding films are crafted from various polymers and composites, often layered for maximum performance:

- PET (Polyethylene Terephthalate): Offers strength, clarity, and recyclability.

- PP (Polypropylene): Lightweight and cost-effective, with good sealing properties.

- PE (Polyethylene): Flexible and widely used for peelable film applications.

- Aluminum Foil Laminates: Provide excellent barrier protection, especially in dairy or beverage packaging.

- Bio-Based Polymers: An eco-friendly option for brands prioritizing sustainability.

Key Features and Benefits

Lidding films are more than just protective covers; they bring a wide array of advantages to the food industry:

- Freshness and Shelf Life: Their barrier properties protect food from oxygen, moisture, and contaminants.

- Tamper Evidence: Seals act as proof of product integrity, building consumer trust.

- Convenience: Peelable and resealable options cater to on-the-go lifestyles.

- Branding Opportunities: Films can be printed with high-quality graphics to enhance shelf appeal.

- Versatility: Compatible with various substrates, including plastic, aluminum, and paperboard containers.

- Sustainability: Many lidding films are recyclable, compostable, or use reduced plastic content.

Applications of Lidding Film

Lidding films are used across a broad range of industries, particularly in the food sector:

- Fresh Produce: Extends the freshness of fruits, vegetables, and salads.

- Meat, Poultry, and Seafood: High-barrier films prevent spoilage and leakage.

- Dairy Products: Yogurt, cheese, and milk-based products rely on peelable or die-cut films.

- Ready Meals: Heat-resistant films allow microwave or oven cooking directly within the package.

- Snacks and Confectionery: Resealable options ensure convenience and portion control.

- Beverages: Coffee capsules and drink cups often use foil-based lidding.

Lidding Film and Sustainability

As consumer demand shifts toward eco-conscious packaging, lidding films are evolving:

- Recyclable Structures: Single-material films make recycling easier.

- Compostable Options: Films derived from plant-based materials reduce environmental impact.

- Lightweight Designs: Less material usage reduces overall packaging waste.

- Energy Efficiency: Advanced production methods lower carbon footprints.

The Future of Lidding Film

The lidding film market is expected to continue growing, driven by convenience foods, sustainability trends, and e-commerce packaging. Smart packaging innovations—such as films with QR codes, freshness indicators, or antimicrobial coatings—are set to revolutionize consumer experience while further enhancing safety and sustainability.